- RECARO

-

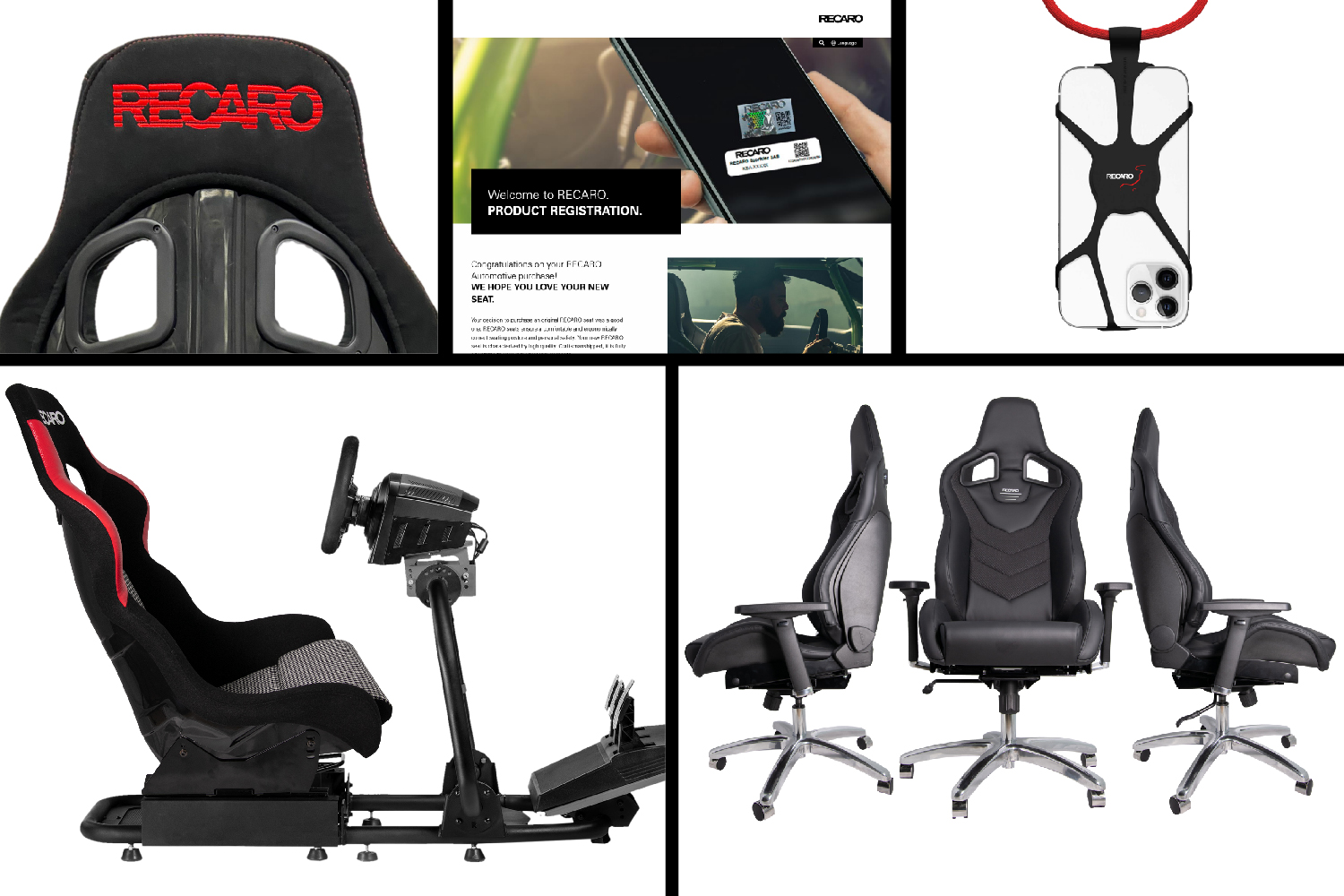

Dynamic

- Product Overview

- RECARO Podium CF

- RECARO Podium GF

- RECARO Podium GF “24H Le Mans” Limited Edition

- RECARO Pole Position (ABE)

- RECARO Sport C

- RECARO Sportster CS

- RECARO Cross Sportster CS

- RECARO Sportster GT

- RECARO Speed-V

- RECARO Speed

- RECARO Cross Sportster ORV

- RECARO Automotive Collection

- RECARO Production Vehicles

- RECARO Store Finder

- RECARO Seat Fit Guide

- Race

- Comfort

- Classic

- Commercial

- Lifestyle

- Services

- Shop

![[Translate to English (US):] Innovation [Translate to English (US):] Innovation](https://cdn.recaro-automotive.com/fileadmin/_processed_/8/0/csm_recaro-quicklink-footer-innovation-1200x720_d07c431d31.jpg)